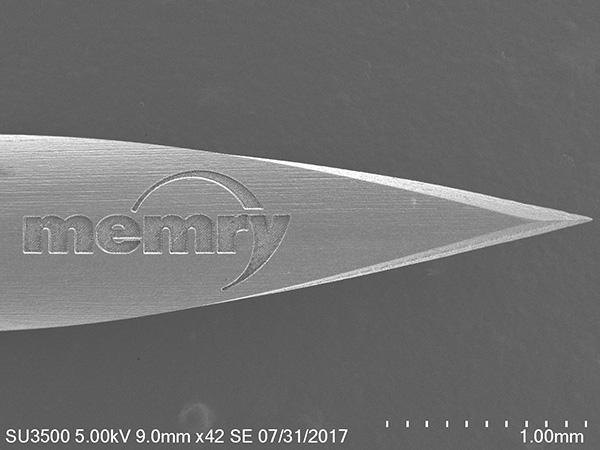

Laser-cutting was first applied to the manufacturing of medical devices in the 1980s. Since then, continued advancements in laser technologies have enabled cutting of increasingly smaller and complex features. Today, feature sizes as small as 0.0005” (12.7 µm) can be realized. Memry has developed a laser platform that ensures precision, quality, dedicated laser engineering and high volume production.

Memry’s Nitinol laser processing technologies are ideal for manufacturing intricate, finely structured devices. The non-contact, precision and low thermal input characteristics of laser processes have made lasers the technology of choice at Memry for welding, cutting/ablation and marking. More specifically, the extreme thermal-sensitivity of Nitinol’s microstructure and thermomechanical performance makes low heat input secondary processes a necessity.

Memry utilizes an array of state-of-the-art custom Fiber and Femtosecond laser systems that were developed internally, specifically for the cutting of Nitinol medical devices. The internal knowledge of the Memry systems is ideal when processing Nitinol. Our extensive laser-cutting capabilities allows for the machining of tube, sheet, strip, foil, and even solid wire and rod. Typical Nitinol material thicknesses that are laser-cut range from less than 0.001” (25 µm) to 0.040” (1 mm).

Memry’s Nitinol laser processing technologies are ideal for manufacturing intricate, finely structured devices. The non-contact, precision and low thermal input characteristics of laser processes have made lasers the technology of choice at Memry for welding, cutting/ablation and marking. More specifically, the extreme thermal-sensitivity of Nitinol’s microstructure and thermomechanical performance makes low heat input secondary processes a necessity.

Memry utilizes an array of state-of-the-art custom Fiber and Femtosecond laser systems that were developed internally, specifically for the cutting of Nitinol medical devices. The internal knowledge of the Memry systems is ideal when processing Nitinol. Our extensive laser-cutting capabilities allows for the machining of tube, sheet, strip, foil, and even solid wire and rod. Typical Nitinol material thicknesses that are laser-cut range from less than 0.001” (25 µm) to 0.040” (1 mm).

Pulsed-Fiber laser-cutting systems have excellent beam quality and high power capabilities. These systems are typically applied to cutting thicker components and at higher processing speeds. Examples of components well suited for Pulsed-fiber laser-cutting include structural heart valve frames and AAA stent grafts.

Femtosecond ultra-short pulse laser systems are utilized at Memry for the most demanding applications, reaping the benefits of the athermal process and the highest beam quality and resulting kerf width currently possible (i.e. < 0.0002” or 5 µm). As a general guide, Nitinol tubes with a thin wall (< 0.005” or 125 μm) and designs with thin struts or small geometrically critical features (i.e. < 0.004” or 100 μm) will benefit from a Femtosecond laser-cutting process. Example Femtosecond laser-cutting applications include neurovascular and ophthalmology devices where extremely small low profile designs are critical. Using galvanometric scanner beam delivery optics, partial penetration ablation of Nitinol is also possible with the Femtosecond laser source. With this technology unique surface texturing for drug delivery or even for creating echogenic features for increased visibility of the device in the OR is possible.

Femtosecond ultra-short pulse laser systems are utilized at Memry for the most demanding applications, reaping the benefits of the athermal process and the highest beam quality and resulting kerf width currently possible (i.e. < 0.0002” or 5 µm). As a general guide, Nitinol tubes with a thin wall (< 0.005” or 125 μm) and designs with thin struts or small geometrically critical features (i.e. < 0.004” or 100 μm) will benefit from a Femtosecond laser-cutting process. Example Femtosecond laser-cutting applications include neurovascular and ophthalmology devices where extremely small low profile designs are critical. Using galvanometric scanner beam delivery optics, partial penetration ablation of Nitinol is also possible with the Femtosecond laser source. With this technology unique surface texturing for drug delivery or even for creating echogenic features for increased visibility of the device in the OR is possible.